Brittle rock material.(Image from Paixin.com)

Evidence has shown that the strengths of geological materials vary during failure processes. Nevertheless, how to quantitatively characterize this still currently remains challenging. Dr. GUO Songfeng, Professor QI Shengwen, and Drs. ZHAN Zhifa and ZHENG Bowen, of the Key Laboratory of Shale Gas and Geoengineering at the Institute of Geology and Geophysics (IGG) of the Chinese Academy of Sciences, have presented an innovative experimental method for obtaining strength parameters during progressive failures. They also recently proposed a plastic-strain dependent strength model. Their proposals were published in Engineering Geology.(Link)

It has been revealed that the progressive failure processes of geological materials include rock involved crack initiations, propagations, damages, and eventual failures (Bieniawski, 1967; Martin, 1997), during which the strengths of the materials evolve. However, the quantitative correlations between the strengths and progressive failures have always presented challenging problems.

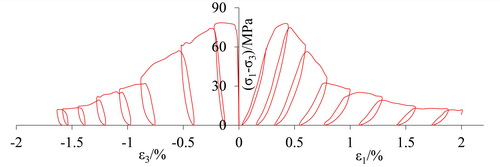

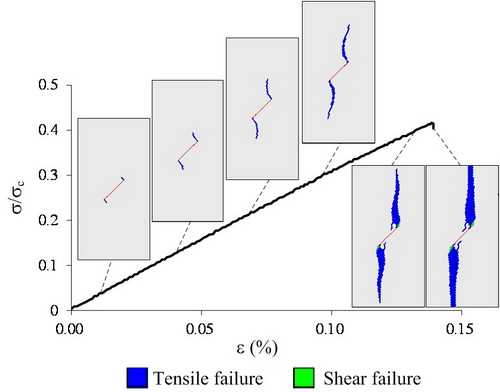

Under the guidance of Professor QI Shengwen, Dr. GUO Songfeng et al. were able to put forward a creative experimental procedure for the determination of the gradual strengths during the progressive failures of geological materials subjected to natural and artificial disturbances. These disturbances included metabolic amplitude cyclic loading-unloading compression tests under different confining pressures. Also, further studies have indicated that, for brittle rock material, both the shear strength parameters and tensile strengths vary during failure processes, including cohesion weakening, frictional strength mobilization, and losses in tensile strength (CWFS-TL). Then, the strength model was verified by utilizing the well-known experiments conducted by Horri (1986) for crack growth in specimens with pre-existing flaws.

This research study was supported by the National Basic Research Program of China (973 Program), and the National Natural Science Foundation of China. Authors: GUO Songfeng, QI Shengwen, ZHAN Zhifa, and ZHENG Bowen.

Fig. 1 Metabolic amplitude cyclic loading-unloading compression test

Fig. 2 Simulated crack growth of a rock specimen with a non-persistent joint based on the strength model

Contact:

GUO Songfeng, QI Shengwen

The Institute of Geology and Geophysics, Chinese Academy of Sciences

Phone: 86-10-82998660

E-mail: guosongfeng09@mails.ucas.ac.cn